2 mins read//

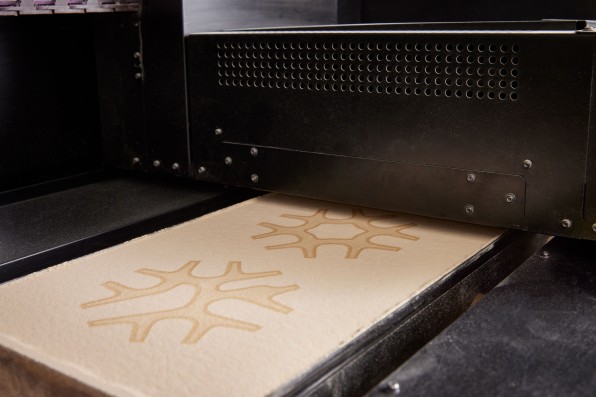

Inside a workshop near Boston, a six-foot-long 3D printer is churning out furniture that looks indistinguishable from wood, built layer by layer from sawdust that otherwise would have been wasted.

“We’re preventing trees from being cut down,” says Andy Jeffrey, CEO of Forust, the startup that created the printer, which is the winner of the art and design category of Fast Company’s 2022 World Changing Ideas Awards. In the U.S. alone, he says, nearly 100 million tons of sawdust is generated each year, the equivalent of 30 to 40 million trees. Much of that sawdust is either incinerated or sent to landfills.

Because the process can sculpt an object as it prints, it’s possible to design pieces that are more intricate than could easily be made with traditional carving. The company is now producing a variety of products, from sculptural bowls to car parts, and redesigning others, like golf tees with an easier-to-use shape that couldn’t be made through traditional manufacturing.

Since sawdust is widely available around the planet—along with other wood waste like materials from construction sites—the printers could be used anywhere and help eliminate supply chain challenges that exist for wood now. “It doesn’t make sense to actually ship sawdust around the world,” he says.”The type of manufacturing we envisage is a more distributed manufacturing model where you’re not reliant on massive supply chains to ship sawdust to a big central location, and then ship products all around the world.”